|

Model Year

|

2023

|

|

Motormodell

|

WP10G220E343

|

|

Nennleistung

|

162 kW (220 hp) @ 2000 rpm

|

|

Verschiebung

|

9.7 L

|

|

Rated Speed

|

2000 rpm

|

|

Typ

|

4-stroke direct injection diesel

|

|

Rated Load

|

5000 kg (5 t)

|

|

Betriebsgewicht

|

16800 kg (16.8 t)

|

Durable Second-hand Caterpillar SEM655D Wheel Loader High Cost Performance Construction Equipment

FOB-Preis: $25,000 /Einheit

-

Geld sparen

-

Guter Ruf

-

Wenig Betriebsstunden

-

Maschinenqualität

-

Reiche Vielfalt

Beschreibung

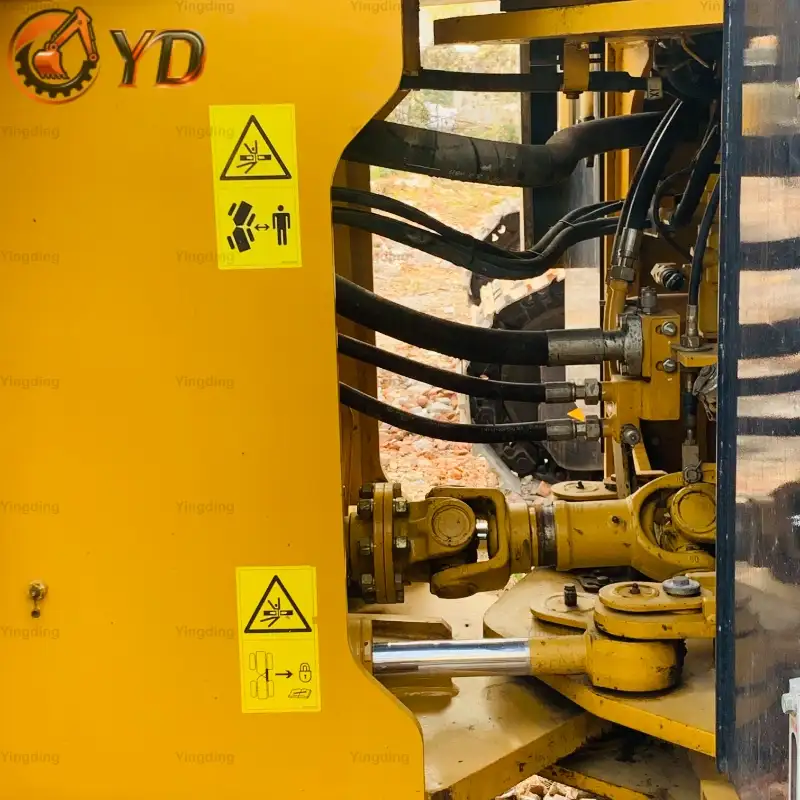

SEM655D Wheel Loader, a 5-ton high-performance star, is equipped with a Weichai WP10G220E343 engine that delivers 162kW at 2000rpm, paired with a 2.7-4.5m³ large-capacity bucket, 177kN maximum breakout force, and 39km/h top travel speed, delivering excellent fuel economy and superior operability for mining, municipal construction and earthmoving tasks.

1. Q: What working conditions is the SEM655D Wheel Loader suitable for? A: It is mainly suitable for medium to heavy-duty working scenarios such as tunnel mucking, earthwork engineering, road construction, mining operations, and municipal engineering. It is especially adaptable to high-temperature environments, plateau tunnels and narrow operation sites.

2. Q: How is the fuel economy of the SEM655D Wheel Loader? A: It is equipped with a Weichai National III electronically controlled high-pressure common rail engine and a Cat technology single-variable hydraulic system, which significantly improves energy efficiency. Its fuel consumption rate is 210g/kW·h, which is more fuel-efficient than traditional models of the same level.

3. Q: What advantages does the SEM655D Wheel Loader have in operation efficiency? A: It adopts an optimized side-dumping bucket with a larger bucket arc radius, which is suitable for shoveling bulk materials. The three-lever pilot control enables continuous lifting and side-dumping operations, and the small turning radius and fast traveling speed further improve operation efficiency.

4. Q: What pain points does the SEM655D Wheel Loader solve in different working scenarios?

(1) Tunnel Mucking Pain Points Solved: ● High-temperature adaptability — Equipped with a high-temperature water tank and a Cat technology cooling package, it can avoid oil overheating and boiling when working continuously in high-temperature environments up to 52 degrees. ● Operational stability — Increased counterweight improves the tipping load and overall stability of the machine, adapting to the complex environment of tunnel operations. ● Cost reduction — The side-dumping bucket can be swapped left and right and with new buckets, reducing replacement costs.

(2) Earthwork and Mining Operations Pain Points Solved: ● Load-bearing reliability — Optimized SO28 and SO32 axles have higher load-bearing capacity and reliability, which are suitable for heavy-duty operations such as shoveling ore and coal. ● Efficient shoveling — The two-hinge design of the bucket enables quick and labor-saving unloading, and the added viewing window facilitates accurate shoveling. ● Durability — The body is equipped with anti-collision beams, and the bucket teeth are wear-resistant, which prolongs the service life under harsh working conditions.

(3) Road and Municipal Engineering Pain Points Solved: ● Flexible operation — It has flexible steering and a compact structure, which is suitable for narrow operation spaces in urban areas and road maintenance scenarios. ● Comfortable operation — The mold-formed panoramic cab is equipped with a high-back suspended adjustable seat, air conditioning and low-noise design, reducing driver fatigue during long-hour operations. ● Convenient maintenance — The split structure of the gearbox and torque converter simplifies maintenance and reduces maintenance costs by half.

5. Q: How about the maintainability and after-sales support of the SEM655D Wheel Loader? A: It is designed with convenient maintenance, including hydraulic and braking systems with pressure measuring joints, enlarged side doors to increase maintenance space, and centralized lubrication interfaces at key parts. There are many service points nationwide, and it can obtain support from Caterpillar’s global service system, making maintenance and repair more convenient.

6. Q: What advantages does the SEM655D Wheel Loader have in operational comfort and safety? A: The cab is equipped with Caterpillar MAC shock absorbers, push-pull side windows, and a cab supercharging and dust removal function. The three-level alarm integrated instrument facilitates detection. In terms of safety, the cab noise meets national standards, the maintenance points adopt a three-point contact design, and the left and right escalator floors conform to ergonomic requirements.

Verwandt Produkt

Wir sind spezialisiert auf den Verkauf von hochwertigen gebrauchten Baggern und anderen Baumaschinen sowie auf die umfassende Ersatzteilversorgung.-

Gebrauchte Liugong 856H Radlader-Baumaschinen mit hohem Preis-Leistungs-Verhältnis zu verkaufen

-

Gebrauchter XCMG LW500KV Radlader in gutem Zustand – Lieferant für Baumaschinen

-

Gebrauchte CAT 966H Klammerlader zum günstigen Preis – Lieferant für Baumaschinen

-

Gebrauchter SDLG 958L Radlader im Angebot – Lieferant für Baumaschinen

-

Hot Sale Used XCMG ZL50GN Wheel Loader Construction Equipment for sale

-

Gebrauchter CAT 966H Radlader in gutem Zustand zu verkaufen

-

Gebrauchter Radlader SDLG 956F in gutem Zustand zu verkaufen

-

Robuster, gebrauchter Radlader SDLG 958F für Baumaschinen zu verkaufen